|

Pryco, Inc. manufactures

Day tanks, Sub-Base tanks, Pump Sets, and other

high-tech equipment for sophisticated fuel systems for emergency,

stand-by, co-generation power systems, and boiler fuel systems.

Since 1980, they have been a

worldwide supplier of fuel systems for all types of power systems,

boiler plants and automatic lubrication systems. |

|

What makes their Day

Tanks exceptional is the use of hard wired simple plug in relays as

the logic in the controls so your service people can just replace a

readily available two or three pole relay to get your system up and

running without having to wait for a custom replacement PC Board as is

standard in the industry. More exotic PLC controls are available in

the FCM and Evolution PLC systems.

Pryco Day Tanks

come in three general design types: Standard, Manual, and

Trim. The Standard and Manual tanks have the same physical

dimensions. The Manual tanks however do not have a mounted pump,

motor, float switch, and related controls. The Standard and the Trim

tanks have the same standard equipment (see Standard Features);

however, the Trim design has a smaller footprint and is taller.

Controls are available with microprocessor or old school relay logic

designs.

Versions are

available in seismic configurations and to meet any state or local

code.

New York City 25PSI Day Tanks.

Each tank (and

double wall containment area, if applicable) has a 2” Atmospheric

Vent.

If the tank is

UL 142 Listed, an Emergency Vent is added. The size of the UL Emergency

Vent depends upon the wetted surface area of the tank and is shown to

the right. If the tank is UL Listed and double walled, the same size

Emergency Vent is also added to the double wall containment area.

Day Tank Standard Features

include:

-

Removable 6½" Square Inspection Plate with

Gasket

-

Fuel Level Gauge

-

Heavy Duty Float Switch

-

“Press-to-Test” Switch

-

"Pump Running" Indicator Light

-

Four - 1" NPT Threaded Pipe Connections

-

One - 2" NPT Threaded Pipe Connection for Tank

Vent

-

Tank Drain (Sized To Tank Capacity)

-

1/3 HP thermally protected, 120 VAC,

single phase,

60hz, motor

-

2 GPM bronze gear pump w/stainless steel shafts

-

Lift Lugs (on tanks 50 gallons and over)

-

Removable top cover

-

Epoxy coating inside

-

Tanks are fabricated of heavy gauge steel by

certified welders.

-

Each tank complies with NFPA 30 and is tested

to 5 PSI

-

Pryco Medium Gray exterior

paint

or Caterpillar Yellow,

Kohler Beige, Cummins Green, Generac Tan, MTU Gray and Fire Pump Red

colors or they can color match at little or no additional charge.

|

|

Sub-Base Tanks:

These are

designed specifically for generator set mounting. The physical size of

each depends upon the foot print of the generator set and required

capacity. Sub-base Tanks are available in a Standard or a UL Listed

design. Each has the following characteristics:

-

Heavy Gauge Steel - 7-gauge for the top and side channels; 12-gauge

for bottom, ends, and internal baffles.

-

Internal Structural Baffles - located every mounting point and a

hot/cold fuel separation baffle.

-

Drain - 3/8” in tanks up to 200 gallons and 1” in 200+

gallon tanks.

-

Connections - (1 ea.) 1½” for fuel level gauge; (2 ea.) 2”

NPT for lockable fill cap and for vent; and (2 ea.) ½” for engine

suction and for engine return.

-

Welded by Certified Welders and

Tested to 5PSI.

-

Finish - Primer and choice of industrial color enamel.

-

Standard or UL

Listed Sub-base may be fitted with

Double-Wall (“Secondary Containment”) construction. Custom designed tanks

can accommodate large capacity Double Wall and

Rupture Basin requirements.

-

UL Listed

Sub-base Tanks have additional sized vents for the tank and the double

wall area, if

-

present. UL

Listed Sub-Base Tanks are restricted to: Width cannot exceed 82” -

Height cannot exceed 30” and Capacity - 2000 gallons or less.

The heavy construction of Pryco built Sub-Base Tanks allows us to offer

every tank with lifting eyes or rings capable of lifting the entire

assembled generator set. Whether you need a standard tank for an

indoor application, outdoor destination, factory housed unit, or a

custom designed tank, we can meet your fuel tank needs.

|

|

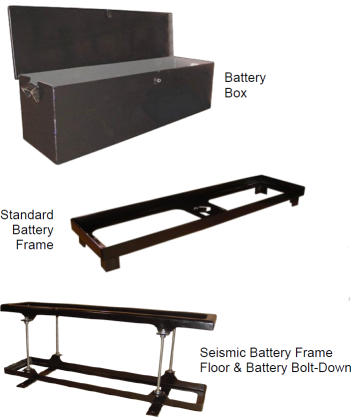

Battery Boxes, Battery Racks, and Battery Frames:

Both basic and seismic designed to your specification and

battery types. Also Step or Tiered Battery Racks. Available

for Lead Acid group 4D or 8D batteries, in addition to Nickel Cadmium

(NICD), Nickel Iron (NIFE) Batteries and others. Boxes are hinged,

lockable, with handles, designed for outdoor use, and available with a

heater and thermostat. A battery disconnect switch is an available option

mounted on the box. Battery Frames are formed 7 gauge. Battery

Boxes are typically Glossy Black

or optional

Caterpillar

Yellow, Kohler Beige, Cummins Green, Generac Tan, MTU Gray and Fire Pump

Red colors or they can color match at little or no additional charge.

|

|

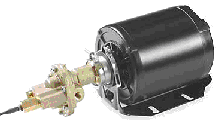

A full range of accessories is available:

Electrical:

Motors, Motor Starters, Fuel Alarms, Horns, Switches, and Lights. Circuit

Breakers, Float Level Switches, Leak Detectors, Heaters & Thermostats,

Remote Pumping Units, Remote Reading Level Gauge, Remote Fill Panels,

Reverse Flow Controls.

Mechanical:

Pumps, Fuel Oil Coolers, Mechanical Visual Level Gauges, Manual

Fuel Fill Locking Caps, Wall Mounting Brackets, Pipe Stands, Sight

Glass, Filter Minder, Priming Tee, Gauges, Fuel Line Strainers & Filters,

Fuel Filter/Water Separators, Vent Caps & Kits, Pressure Release Valves,

Pipe Connection Ports, Weather Proof Day Tank, Rupture Basin, & Sub-Base

Tank Covers, Pump Set Enclosures, Drain Petcock Valves, Drains, Check

Valves, Solenoid Valves, Manual & Motorized Ball Valve, Flow Switches,

Temperature Switch, Rupture Basins, Auxiliary Rotary or Piston Hand Pumps.

|