|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earthsafe Systems Inc. designs and builds

from simple to complex diesel fuel polishing systems, controls, and

transfer equipment for emergency power. Their more sophisticated

and elaborate systems are used at

critical technical facilities such as data centers and hospitals to

provide continuous reliable operation.

Established in 1990, Earthsafe

has experience with the leading design engineers,

architects,

and builders of technical facilities throughout the world and can

integrate your fuel and/or DEF Urea system with building network controls. |

|

|

|

|

|

|

HDPE

Rectangular & Square Tanks: Custom Built

tanks to meet your space requirements. Get the needed

gallonage and fit within your space constraints. A perfect

package with all the required

accessories at a great price!

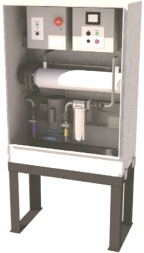

Fuel Polisher (M3 Series):

Fuel Polishing is an advanced

multi-stage form of filtration critical for generators to start and

run reliably. As diesel fuel ages, particulates form which can

increase the wear on generator engine parts, block filters, and

corrodes tanks. Fuel tanks accumulate water through condensation

encouraging bacterial growth. Diesel engine emissions technology

requires higher purity fuel to prolong engine life. This is

essentially an Automatic Fuel Oil Maintenance System which

continuously maintains your fuel source via a scheduled removal of

water and particulate from your tank.

We offer both portable and

stationary designs for a wide spectrum of industries. Their automatic

mechanical processes was created to successfully clean sludge, water,

microbial contaminants, and other sediments found in a variety of

diesel fuel, biodiesel, hydraulic fluid, and light oils being stored

in above or below ground tanks. Most models are designed for direct

integration into most standard brand factory supplied generator

control and monitoring systems and utilizes Racor replaceable

filters. These are available as indoor packages or mounted within

stainless steel outdoor enclosures.

|

DEF Urea Tanks & Pumping Systems for Generator SCR

emission control:

Integrated Systems for

Generator Diesel Exhaust Fluid (DEF) Urea. Includes Stainless Insulated Tanks, DEF Tank Fill

Systems, DEF Urea Pumps and Filters, DEF Urea Heating and Cooling

Systems. DEF

requires specialized storage to maintain required quality for

generator exhaust treatment. DEF is a highly pure chemical fluid

and must be stored in a specially designed tank to maintained closely

to its 32.5% concentration of urea in 67.5% de-ionized water.

Most diesel engines with Selective Catalytic Reduction (SCR) emission

systems are specifically programmed for optimal performance at this

ratio. DEF fluid is in used to reduce the NOx pollutants, in

exhaust gases. DEF must be protected both from low temperature

freezing (12ºF) and high temperature degradation. The quality is

critical since many diesel generators cannot legally be operated

without effective in specification pollution control.

DEF Urea Head Tanks:

They typically mount on the wall or on a stand

within the enclosure and refill the standard DEF tank on the generator

engine by gravity flow.

DEF Urea Storage Tanks:

The DEF Urea Day Tanks provide

safe storage of DEF Urea for generator SCR emission controls. The

cubic design saves space in crowded generator rooms or enclosures.

The UM5 is available as single wall, double wall, or double wall

insulated in stainless steel, HDPE inner with stainless steel outer

shell, or HDPE plastic. This can be customized for the application

with instrumentation, heaters, and pumps. Controls interface with

generator systems with High, Low, Leak contacts or optional Modbus /

BACnet connectivity.

Caterpillar DEF Urea Buffer Tank Refill

Interface

The UM5BTI Cat DEF Urea Buffer

Tank Refill Interface provides automatic refilling for Caterpillar SCR

DEF Urea Buffer Tanks from remote bulk storage tanks and pumps. The

unit is installed adjacent to the the buffer tank to provide the

required low pressure feed to the buffer tank. Controls interface with

generator systems with High, Low, Leak contacts or optional Modbus /

BACnet connectivity.

Air-Assisted Compressor Packages for SCR Systems:

Some engine manufacturers require specific models to utilize

air-assisted DEF urea injection in their SCR systems. These are

typically on large engines in which the large size of the exhaust duct

requires an expanded yet uniform mix of DEF urea and the exhaust

gases. This system adds compressed air to the DEF urea injector to

enhance the atomization of the urea fluid and theoretically should

reduce the combination of fuel and DEF Urea consumption. Earthsafe is

supplying these systems.

|

|

|

|

Day Tanks and Refill

Controls (M5 Series):

Earthsafe has provided

thousands of day tanks worldwide, all with their modern and reliable integrated network ready

control panels for today's building systems. As generator sub-base tanks have

replaced day tanks in many applications, Earthsafe has adapted its

refill systems to the special challenges of the application. Day Tanks

are available in a full range of sizes 25-2,500 gallons as

double wall, 150% or 200% Rupture Basin, standard UL 142 or fire-rated

UL 2085 units. The complete package is quoted with all the

accessories you want and require.

Day Tank

and Sub-Base Tank

Refill Systems (M50

Series):

Integrated Level and Fuel Transfer

Control systems. The Earthsafe M50 is

Day Tank Refill System for generator fuel. The system combines fuel

transfer pumps and control valves with tank level sensors, analog level

transmitters, and leak sensors in a compact design with integrated

controller.

-

Make Any Mini-Bulk

Tank a Day Tank:

User or Contractor supplied UL142 fuel tanks can be used with a M50

unit to provide a reliable and cost effective day tank system.

-

Retrofit Control to

an Old Day Tank:

Older day tank equipment can be improved and integrated by stripping

off the old controls and providing a M50 unit.

-

Generator Sub-Base

Tank Refill: Widely

used generator sub-base tanks can be monitored and automatically

refilled with an M50 unit.

-

M51 Auto Inlet Valve

Control + Flow Limit Valve

-

M52 Auto Inlet Valve

Control + High Stop Valve

-

M53 Auto Inlet Valve

Control + Return Flow Pump

-

M54 Duplex Fuel Supply

Pumps

-

M55 Fuel Supply Pump + Return Flow

Pump

Duplex Pumps and Motors (M2 Series):

Duplex Pumps provide redundancy for

critical fuel supply. Their duplex pumps are based on high performance

gear pumps with excellent suction characteristics to assure

performance. Pumps are available from 3 to 300 GPM and in

the full range of HP and Voltages. Pump sets include all valves,

gauges, sensors, and accessories in a pre-assembled and tested module.

Hot Engine Coolant or Hot Water Pump & Motor systems for remote heat

exchangers or radiators are also available.

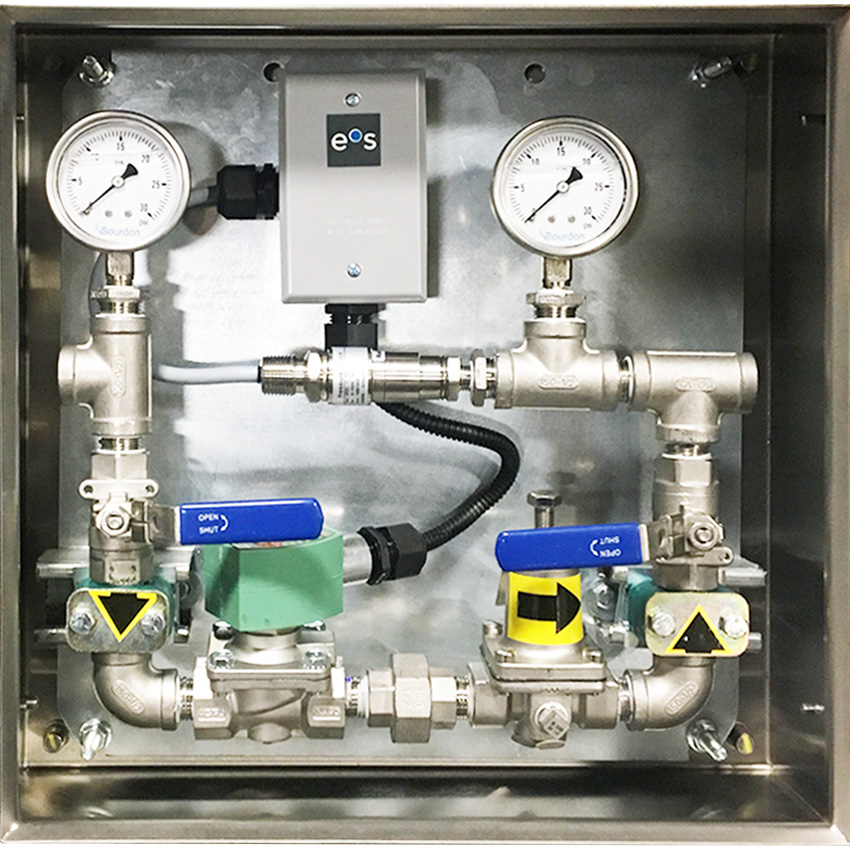

Tank Fill Stations &

Remote Fill Boxes for Diesel Fuel or DEF Urea (M4

Series):

The ESS M4 series fill stations are

known for safety, performance, and good lucks. The stainless steel

cabinets recess into walls for use in and around buildings.

Controls, sensors, and shutoff valves assure safe filling where tanks

are remote or cannot be readily observed in buildings. Pump units

are available for 25-600 GPM. All units serve single or multiple

tanks. These easily accessible units are available for Diesel, Aviation,

and E-85 fuel in addition to DEF Urea. A variety of optional

features for manual or automatic operation, mounting, lockable door,

shutoff ball valve, overfill pump, and spill containment.

|

|

|

|

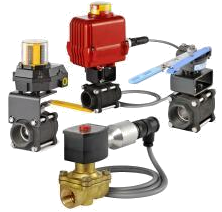

Fuel System Controllers,

Accessories, and Network Products:

Earthsafe Controllers manage reliable

fuel supply to generators in critical applications. Controllers are

network ready for application to critical fuel supply in data centers,

hospitals, security, and communication facilities. They are also used for

critical life safety generator applications in multi-story urban

buildings. A full range of Level Senders, Leak Detectors, Vacuum

Sensors, and Control Valves are available

to offer a complete and integrated system.

|

|

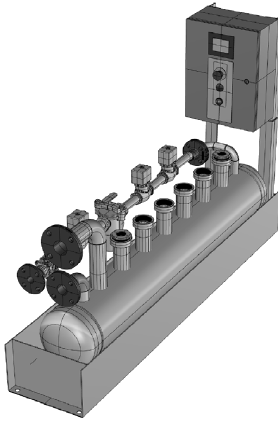

Fuel Header Tank System:

Earthsafe manufactures complete packaged

Fuel Header Systems for

Generators in Buildings or Rooftops with limitations for fuel storage. The

header is fed with fuel from bulk storage tank using a duplex pump system.

The flow is initiated and continues through the generator run event.

Excess fuel overflows from the header back to the storage tank. Where

required, an ON‐OFF refill is available with a duplex overflow pump /

reservoir where fuel storage is above-ground tanks above the header

level. This is an ASME Code Vessel.

A fuel header system is designed to

provide fuel to multiple generators, where there are severe regulatory

restrictions to the volume of fuel that can be stored in the generator

room. The header is typically up to 330 gallons and 8” to 24” diameter pipe

which runs 10' to 20' long or the length of the room to serve all the

generators. The pipe is sized to be less than the

regulatory limit for fuel storage quantities in the room.

The generators draw fuel from the

header pipe, and return fuel to the header pipe. The fuel supply pumps draw fuel from

a bulk tank and pump to the header inlet. The header outlet is a gravity

overflow back to the bulk storage tank.

Redundant Master

Controllers interface with the facility PMS, (Power Management System),

to allow the operators to have comprehensive monitoring of the fuel

system. Fuel fill stations, fuel filtration polishers, and duplex fuel

transfer pumps are available.

The M5H model below is a compact packaged design for an individual

generator set and can be placed within an enclosure.

|

|

Fuel & DEF Consumption

Monitor System (GC3):

Multi‐Function Diesel and DEF Monitor for Reliable

Generator Start and Run in addition to building network integration:

Diesel Fuel

·

Level Gauging and Leak Detection

·

Fill Control and Overfill Protection

·

Refill from Remote Bulk Fuel Tank

·

Filtration Polishing Control

·

Temperature Control

·

Filter Monitoring

·

Quality Monitoring: Particulate / Water

·

Consumption Measurement

Diesel Exhaust

Fluid (DEF)

·

Quality Monitoring: % Concentration

·

Level Gauging and Leak Detection

·

Temperature Monitoring / Control

Accessories:

Sensors, Transmitters, Particulate or Water Analyzers, Flow Switch,

Pumps, Valves, Heaters, Enclosures.

Lube Oil - Waste Oil

Make-up Systems & Tanks System (LM6):

A

Lubrication Oil Make-Up Systems is designed to

extend the onsite oil-change interval period to permit longer run times

and allow the technician to check the oil level without shutting down the

engine for a visual inspection of the dipstick.

• Available in Cubic Steel, Stainless Steel, or HDPE

• Accessories: Vent Caps, Direct Read Gauge,

Inspect Port, Fill, Suction Pipe and Return Fittings

• C1 Tank Monitor Panel with High, Low, Leak

Alarm, Output Relays, 4-20mA Analog Transmitter and Leak Sensor

• The LM6 Tank is a compact storage tank for

oil used in and around generators enclosures. The tank system can be

equipped with pumps and controls to provide a complete oil supply system

for generators.

• Optional Accessories: Dual Wall, Tank Insulation, Tank

Heater

Gen Evo Fuel System:

Generator fuel systems are

configured in a wide variety of systems to suit safety, compliance, and

operational requirements in and around buildings. Most often they are

designed and built, or cobbled together, using independent fuel gauges,

pumps, day tanks, and other components that are difficult to commission

and operate as an integrated system. The Franklin Evo has a heritage of

integrating fuel tank level gauging, leak detection, and pump control -

and an unmatched global network of certified technicians.

The evo controller is well known for

tank level gauging, leak detection, fill station high level alarms,

secondary containment monitoring, and

operating submersible pumps. The GenEvo controller extends these

capabilities to:

Day Tanks: Evo

level probes perform precision gauging of day tank fuel levels, and

programmable refill start and stop functions. Day tank inlet solenoid

valves, supply transfer pumps, or overflow return pumps are all integrated

into the evo control.

Filter Polishers:

Evo controls the timing of filter polisher circulation pumps, and monitors

filter status. evoGen elements are available as Filter Polisher units fed

by remote submersible pumps, or with on-board positive displacement

suction pumps.

Duplex Pumps: Evo

controls its native FE Petro submersible pumps. It also operates and

monitors positive displacement suction pumps where used for more precise

low flow control or higher pressure required in high rise buildings.

Tank Fill Stations:

Evo controls remote tank fill stations with high level alarms, fill pipe

valve control, remote tank level % Full indication, and multi-tank fill

selection.

Diesel Fuel Consumption Monitor:

Includes the sensors, (inlet flow, outlet flow, inlet flow temperature,

outlet flow temperature). CAN bus and MOD bus interface included.

DEF Urea

Consumption Monitor:

Includes the sensors, (inlet flow, outlet flow, inlet flow temperature,

outlet flow temperature). CAN bus and MOD bus interface included.

|

|

Fuel Cube Storage Tanks,

Integrated Fuel Storage & Transfer Pump Systems and

Enclosures:

Earthsafe Systems offers a variety of

stationary and portable cube fuel systems and can integrate with all

types of storage tanks, underground or aboveground, carbon steel,

stainless steel, or fiberglass. They also manufacture cubic fuel storage

tanks and equipment enclosures for rental generator and pump plus a host

of other special applications.

|

|

|

|

|

Integrated Modular Fuel

Systems (M9 Series):

These systems

combine the functions of fuel transfer, filter polishing, tank filling,

and control into a single integrated assembly. The units reduce field

labor and costs, speed fast-track projects, and allow for complete

factory testing for remote international site.

|

|

Tank and Pipe Heating

Systems:

Controlled heating systems

for fuel tanks and piping may be required in certain environments to

assure reliable service. When the fuel supply is critical in generator

service, then the heat tracing monitoring and control should be designed

and monitored as with any other part of the fuel system.

|

|

Integrating Fuel Systems

into Building Networks:

|

|

Code, Connect, and Commission

When the hardware is in place,

Earthsafe makes it work. Their engineers have performed programming,

networking, startup, and commissioning at over 1000 technical

facilities worldwide.

Code

They perform programming for PLC

and HMI systems for all major makes. Allen Bradley is their core.

However they also have extensive experience with Siemens, Schneider,

GE, Idec, Panasonic, and Automation Direct. And we can built your

control panels around any of those standards.

Connect

Earthsafe has special expertise

with Ethernet networks – standard or redundant configurations. They

design the systems and cabling, select the switch hardware and cable

components, and program the messaging at network PLC's. Integration

to Building Management Systems (BMS) can be based on BACnet, Modbus, or LON. They coordinate

all monitoring points with the BMS vendor, and then prove all points as

a pre-commissioning function.

Commission

Earthsafe has experience with

startup and commissioning of systems for the worlds most demanding

customers. Their site engineers work with commissioning agents for all

pre-commission documentation and planning. Then they challenge the

system working through all failure scenarios and assessing response

modes.

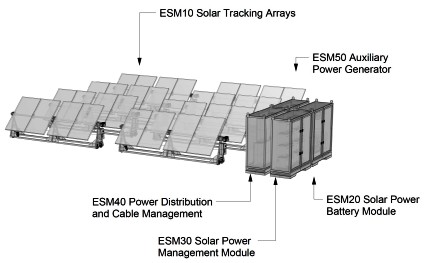

Solar Power - Mobile and Modular

Uninterrupted Power Supply:

Earthsafe Solar Power Systems are

designed for 10 - 100 kW mid-range solar power installations. These are

commercial and industrial systems larger than residential but smaller

that utility systems. Tracking Solar Arrays are the primary power source

with battery storage for 24 hour power, and a generator backup for

shortfalls.

High Reliability is

built into our systems to include battery storage for 24 hour power,

plus an auxiliary generator to supplement battery charging or directly

power loads in emergency.

Designed and Built for Mobility and Adaptive Use: Earthsafe Solar is

designed and built for fast setup and use at specialized site with

minimal site preparation or utility requirements. This makes them ideal

systems for:

-

Special Event

Support

-

Remote Telecom

and Monitoring Facilities

-

Back-Country Base

Camp

-

Humanitarian

Response

-

Telecom and

Communication Systems

-

Security and

First Response Support

-

Rapid Response

and Remote Infrastructure

Power Distribution-Cabling Module:

The Earthsafe

ESM40.100 is a power distribution and cable management system within a

modular weatherproof enclosure. The system is designed for 100A

Photo-Voltaic energy collection with safety disconnects and circuit

breakers. Up to 4 cable reels of 100 feet cable length connect solar

arrays to the system. On the load side the unit safely distributes 120 /

208 VAC power for use through up to 4 reels of 100 feet cable connected

to hi-safety portable distribution boxes.

Solar Power Management Module:

The Earthsafe ESM30

Solar Control and Monitoring Module optimizes the solar collection and

conversion and monitors energy load use for efficiency and safety. The

SC90 Controller is a PLC based controller with Color Touch-Screen HMI

interface and advanced communications. The unit:

-

Controls

and Monitors Solar Array Tracking

-

Optimizes

Solar Array String Output

-

Manages and

Monitors Storage Battery Functions

-

Manages

Grid Connections

-

Manages

Auxiliary Power Generator Functions,

-

Communicates Remotely to Cloud Systems

Upgrade

End-of-Life (EOL) PLC Controllers in Active Data Center:

Full Support for

Legacy and Specialty Controllers.

-

Allen Bradley

Micrologix 1000 and 1500 Obsolete PLC Upgrades

-

Allen Bradley

Micrologix 1100 and 1200 Obsolete PLC Upgrades

-

Siemens S7-200

Obsolete PLC Upgrades

Not Just a Hardware Swap: It

is not simply a matter of a hardware swap.

New application software &

integration to new Network standards. Improve redundancy.

Migrate End‐of‐Life Components to protect against system failure and

extended downtime.

Upgrade & Replace obsolete PLCs & HMI with planned work sequences in

operating environments.

Get the best of new PLC and HMI technology - better performance at lower

prices.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2025 Amstech Power Products, L.L.C. All rights reserved

|

|

|

|

|

|

|

|