|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

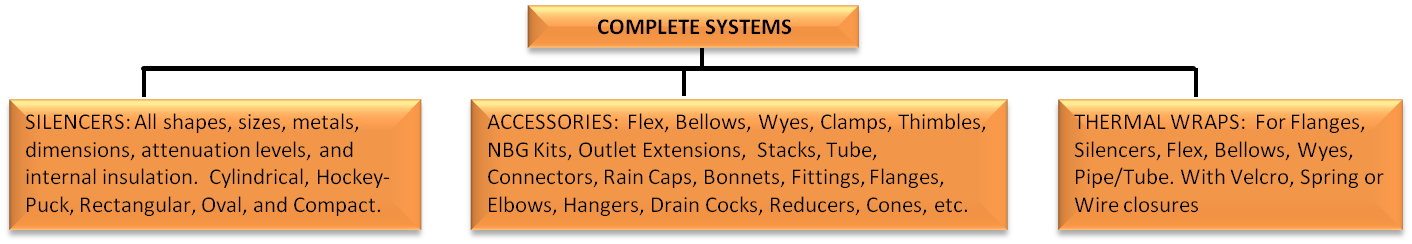

SMS Silencers, Inc.

was established in 1992 and has its headquarters

located in Ontario, Canada making it the closest silencer

supplier to Northeastern USA customers.

In addition to their huge assortment of

standard product offerings they are a custom fabricator of Diesel, Natural Gas,

Propane, and Dual Fuel

Engine Exhaust Noise Reduction Systems.

Whatever your application, they have the silencer and related components to meet your

specifications.

They are truly a "hidden gem in the

world of exhaust

system engineering and

integration".

SMS is a leader in the design of

high performance exhaust attenuation systems. They offer the most complete

selection of reactive and absorptive Engine, Turbine, Power Generation,

Fracking, Oil & Gas, Marine,

Locomotive,

Compressor, and Vent

silencers plus a full array of accessories and options.

Their accessories range from Flex

Connects,

Bellows, Expansion Joints, Wye Connectors, Interlocking or Corrugated

Flex Hose, Thimbles, Clamps, Spark Arrestors, Elbows,

Tubing, Tube Fittings, Mounting Brackets, Rain Caps, Rain Guards, Rain

Bonnets,

Roof Jacks, Brackets,

Nuts and Bolts, Gaskets, Cones, Couplers, Adapters, Exhaust Stacks,

Outlet Extensions, Access Ports, Drain Cocks, Spark Arrestors, and Reusable

Thermal Blankets. |

|

|

|

|

|

|

Amstech has

excelled in the design, application, and marketing of silencers and

exhaust accessories since 1990.

Amstech Power

Products saw a initial need for compact sound attenuated exhaust

silencers uniquely designed for generator enclosures and tight space

like found in buildings located in cities long before anyone else had a

resolution. Amstech conceptualized these designs and was behind the creation of the first

Hockey Puck/Disk Silencers and then the first Oval/Racetrack Silencers

and subsequently sold the first units ever produced!

|

|

Featuring: Great Quality, Variety,

Availability, and Price! |

|

|

|

|

|

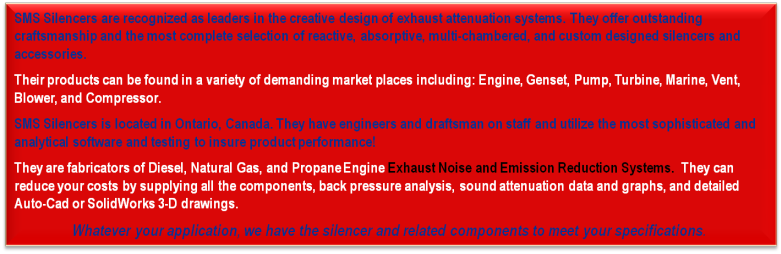

Cylindrical Silencer |

Hockey Puck Silencer |

Rectangular Silencer |

|

|

|

|

|

Hockey Puck or Disk Silencer |

Rectangular Silencer |

Oval or Race Track Silencer |

|

|

|

|

|

Proper packing of

Silencers |

Enclosure

Roof Silencers |

|

|

|

|

|

|

|

|

Flex Connector and

Hardware |

Thimble |

Spark Arrestor Silencer

|

|

|

|

|

|

Cylindrical Silencer on

Enclosure |

Cylindrical Silencer on

Enclosure |

Silencers

with Stacks and Mounts |

|

What makes SMS stand out from the

crowd is that their products

deliver exceptional performance which exceed many customers'

expectations and will meet or exceed their published attenuation ratings,

shipped on schedule, at a good price.

They have a unique passion, dedication, and expertise to satisfy their clients

wishes and offer

ALL the accessories needed to build out your

system at a reasonable price with a quick turnaround time. They have phenomenal technical support and

an extensive in-house production capabilities that can create a hybrid

silencer and associated accessories to meet your wildest requirements!

Others only dream

about their ability to mix standard product offerings and new

innovations for a definitive solution.

Advanced Exhaust

Noise Containment Devices

Give us the most

challenging projects you can imagine, then sit back and be awed by thecreativity and practical application of our in-depth knowledge and years

of experience.

The nearest full

service silencer manufacturer to the Northeast!

Save on Freight and

shipping time.

|

|

|

|

|

|

|

|

|

|

|

|

|

Compact Style Silencer

|

Dual Inlet-Single

Out Silencer

|

End In -End Out

Silencer |

|

|

|

|

|

Flex &

Bellows modules

|

Wye Assembly

|

Flex Assembly

with Flared Flange

|

|

|

|

|

|

|

|

|

|

Stainless Steel Silencer

Side Inlet - End Outlet Silencer |

Amstech

supplied Silencer, Verizon Building,

Ground Zero, NYC

|

Bellows assemblies used

in spaces too tight for a Flex. |

|

Products evolved through

innovation and advancement, not just blind cost reduction.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A full line catalog of Exhaust Tubing

Accessories and Components...

Tube, Elbows, Connectors,

Fittings, Couplers, Clamps, Reducers/Expanders, Cones, Flanges, & Outlet

Extensions. |

|

SMS is an internationally renowned leader in the

production and design of exhaust systems and accessories for diesel,

propane, natural gas, and dual fuel engines. SMS has been in business since 1992 and manufactures

State-of-the-Art exhaust systems with domestic and

international manufacturing capabilities.

They offer the most complete

selection of silencer designs, which include the standard selection of

reactive, turbo, absorptive, vent, and spark arrestor silencers.

They also manufacture

unique space saving, multi-inlet and outlet, and internally insulated

models.

SMS

can reduce your costs by supplying all the components, backpressure

analysis, sound attenuation data, graphs, and detailed Auto-Cad or 3 D drawings.

|

|

|

|

|

SMS

Silencers are found world wide and they provide their clients with

optimal performance in controlling exhaust noise. Typical applications are on some of the

largest stand-by, co-generation, prime power projects in addition to

marine, pumps, construction equipment, compressors, locomotives, and

emission reduction systems.

Standard

silencer models are available in Carbon Steel,

Aluminized Steel,

and Stainless Steel. Custom configurations, Reverse

flow, and Dual Inlet models are no

problem and quoted on request.

Inlet and Outlet connections options include Slip Fit,

Flanges, Straight Tube, and Male or Female NPT’s. A variety of silencer are available

with internal insulation in the shells to lower the exterior body

temperature significantly.

Exterior thermal Blankets are available as an option with Spring,

Velcro, or Hook and Hog Ring type closures, and quoted on request as are

welded on mounting brackets.

SMS Silencers

offers

the greatest variety of accessories which range from Reusable

Thermal Blankets of 1-4 inch thickness, Flex and Tubing Connectors, Clamps, Spark Arrestors, Elbows, Brackets,

Rain Guards, Rain Caps and Rain Bonnets. We also specialize in custom

silencers and accessories to suit your

wildest and most complex

requirements!

Standard models are available in:

Carbon Steel,

Aluminized Steel,

and 304, 409, 316, or 321 Stainless Steel.

Standard Sizes: From 1 ½” to 40” Inlets.

Inlet and Outlet connections options

include:

Slip Fit (slotted I.D.

Cuff), Flanges: (125/150#ANSI or ASA, Caterpillar, Cummins, MTU/Detroit

Diesel, Mitsubishi, Volvo, John Deere), Floating

Flanges, Flared Flanges, Treaded Flanges, Reducing Flanges, Custom

Flanges, Straight Tube, Straight Pipe, and Male or Female NPT’s.

-

Accessories for complete exhaust systems.

-

1”

to 4” Thick Thermal Blankets to fit SMS,

and competitor’s silencers and components.

-

Stainless steel or Aluminized steel is available for

special installation and operating requirements.

-

Sizing program is available

free to ensure the correct

size of silencer.

-

Acoustical and Mechanical engineers with

exotic programs for

application assistance.

-

AutoCad

and Solidworks drawings e-mailed rapidly on request.

-

Offering a quality product at a competitive price to meet

all your exhaust needs.

Thimbles are

available in Carbon Steel with a grey primer or quoted in 304 or 316 Stainless Steel.

They are packed with an

internal thermal insulation, and conform to NFPA 37 & 110. Thimbles are designed to extend

9” into, and 9” outside the building. “A” models are for

combustible walls. “B”

models are for roofs, and non-combustible walls.

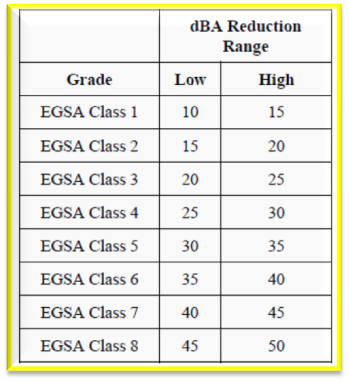

Several Grades are available:

-

Industrial (Commercial) Grade Silencers (Typical Attenuation of 15 -

20

dBa)

-

Residential Grade Silencers (Typical Attenuation of

20 -

25 dBa)

-

Critical Grade Silencers (Typical Attenuation of 25 - 30

dBa)

-

Super Critical Grade Silencers (Typical

Attenuation of 30 - 35 dBa)

-

Hospital Grade Silencers (Typical

Attenuation of 35 - 40 dBa)

-

Hospital Plus

Grade Silencers (Typical Attenuation

of 40 - 50 dBa)

-

Hospital Extreme

Grade Silencers (Typical Attenuation

of 50 - 60 dBa)

-

Spark Arrestors (Typical

Attenuation of 3 - 5 dBa)

-

A variety of special application

individual or silencers pared in series or tandem configurations.

"Producing Engineered Attenuation and Noise Terminators"

SMS will

provide silencers to meet EGSA 201S-2014 attenuation specification.

|

|

|

|

|

|

Silencer advanced designs provide high sound

attenuation and the benefit of providing optimum sound

attenuation in the smallest

package.

-

A variety of compact, low

profile, and space saving silencers are available with or without

internal insulation or spark arrestors: These

silencers are designed for tight spaces like power modules, drop-over

enclosures, marine engine rooms and other space-limited

applications.

The balanced combination of resonator chambers, diffusers and

acoustical/thermal insulation help to achieve targeted sound

pressure objectives.

-

Optional: 1 inch or 2

inches of internal insulation which is selected for thermal and

acoustical performance.

-

Single, dual or triple inlets and outlets are

available.

-

Upper or lower welded on integral mounting

brackets for quick and secure mounting.

-

Custom Built, Special Silencer Systems

The Hockey Puck

(Pancake or Disk) style of silencers provides

you with the optimum noise reduction, and a reduced Genset package. We eliminate the bulk

associated with standard reactive silencers. Now available in 3 distinctive styles

depending on your internal insulation requirements.

The Oval

and or Rectangular shaped

(Race-Track) and

Hockey Puck

series

(Pancake or

Disk

) style of

silencers have a unique construction, which can include 1” or 2” of thermal acoustical

insulation in the shell and significantly lower the exterior

body temperature. A

reduction of the shell temperature enhances SAFETY to personnel,

reduces the ambient air drawn into Radiator, and lessens the wear on

electronics exposed to the extreme temperatures around the engine. These silencers excel in Generator set & Pump enclosures,

small rooms, Marine, and Industrial applications were size and

temperature is a major concern.

The unique construction of some

Cylindrical silencers includes

thermal acoustical insulation in the shell which will provide 300°F

to 500°F reduction in the skin temperature. These excels in

Marine, Industrial, and Generator set enclosure application.

The

Compact series is used when size matters!

The Compact design typically performs considerable better than spiral

silencers of a similar size as it utilizes both reactive and absorptive

technology to attack both high and low frequency noise.

Typically 1/3 the

size of a standard Cylindrical silencer.

Can be internally

insulated plus Super Critical, Hospital, and Extreme Grades are available.

|

|

PRODUCTS

DESIGNED TO EXCEED MOST CUSTOMERS NEEDS…

Their

silencers provide significantly better acoustically than many

competitors cylindrical

reactive and hockey puck designs. They can customize silencers to

meet your unique requirements like having

lower backpressure, have reduced surface temperature,

and can be

physically smaller in size.

SMS

silencer

designs are more efficient at reducing noise and were thoroughly tested on a variety of engines and

the data

was confirmed on all of the eight industry standard frequencies!

They have the ability to combine reactive and absorptive

silencer designs into one unique high performance cost-effective package.

Technical advantages...

-

SMS Hockey-Puck (Disk)

silencers have a lower and more uniform body surface temperature than

some competitors models providing a safer work environment,

not damaging enclosure insulation, and less heat

emanating from the silencer working its way through the radiator and air

intake.

-

Quality material and workmanship

with welds and products designed to last.

-

Smaller and lighter package,

saving in physical space and shipping.

-

Less noise and

lower complaints.

-

Variety of Inlet

and Outlet locations including on the same side.

-

Isolated Exhaust Acoustical Testing.

-

Available Options:

Inspection Ports, Saddles, Mounting Brackets, Drain Valves, Test Ports,

explosion relief vents.

-

Testing and Reports Available Option:

Silencers can be pressure tested to insure no leaks. Customized tests.

-

Lower

backpressure resulting in lower wear on engine components and greater

fuel efficiency.

-

Flexible designs and sizing to meet all customer

requirements.

-

In-house engineers for technical assistance.

-

Inventory for immediate shipment on many

accessory items.

-

Quality Control Program.

-

Over

20 Years of proven performance.

-

Competitively priced.

- Great lead time.

-

Complete line of exhaust accessories

with many built in house.

Replacing a failed or rusted competitors

silencer...

Give us the model number and we can build a

drop in replacement to make your field work a real pleasure! |

|

SMS

continually provides its customers

with...

-

Quality:

Quality is foremost at SMS Silencers, and all of their

employees are dedicated to maintain the highest standards of quality

earned and demanded by our Customers. Their welders are trained to

Canadian Welding Bureau which incorporates CSA standards, and their Quality Assurance

Program.

They are proud of their qualifications and take adherence

to internal and customer specified guidelines extremely seriously. A professional organization

with a variety of certifications and compliances.

The quality team continuously strives

to improve

procedures

and

practices

to best serve our customer base.

-

Engineering & Design: They

utilize a combination of advanced

commercial and proprietary software and tools which have been

developed and refined in collaboration with internal staff, industry

experts, and consultants. These tools are used to provide our

customers with the best solutions and products to meet their current

and future requirements.

-

Versatility:

They

are continually expanding their line of standard products

and monitoring industry trends. In addition,

SMS has the engineering and production

capabilities to design and fabricate special systems to meet your

particular needs and requirements with in house acoustical and

emission professionals with regulatory experience. Their advanced

facilities are

equipped to

handle material of all shapes and sizes.

-

Satisfaction:

A true service oriented supplier! Customer satisfaction is their number one goal. They

achieve this by applying quality design, engineering, and workmanship

with an elaborate quality control program meeting Canadian Welding

Bureau requirements. Versatility to

fabricate systems to meet the end users defined requirements, and the ability to

provide all of this thoroughly and quickly.

All orders are handled in compliance with US and

Canadian standard government regulations.

-

Support:

A variety of experts are available to assist in your system design.

An extensive engineering and technical departments are capable of

in-depth acoustical, mechanical, thermal, regulatory, and emissions

analysis plus system design, fabrication and field installation.

They have a wide range of real field and application experience with

products installed on internationally.

We can bring the solution to you with field

engineering support and installation available and quoted upon

request.

-

Research

& Development:

All

new designs are

engine tested under a variety of load

conditions with the isolated raw exhaust noise using the industry

standard frequencies

to insure they perform in a real time environment. These

accepted octave bands are

31.5, 63, 125, 250, 500, 1000, 2000, 4000, and 8000 dBa. Silencers

are tested for thermal transfer and painted finishes are tested for

adherence and appearance.

|

|

|

|

SILENCER

NOTES: If specific

sound attenuation is required on any project, SMS Silencers engineers are

happy to provide a written guarantee.

Many variables can influence the

calculated attenuation results that are NOT factored into most software

programs and should be looked at during the engineering analysis. Some of these variables

include: variations between engines and testing conditions, ground

elevation and atmosphere conditions, exhaust attachment configuration,

ambient or background noise, environmental landscape, excessive

velocity, mechanical noise, multiple engines. Ambient noise levels are

typically around 65dB, Treated noise levels below that are not

practical.

Caution:

For most applications,

it is recommended that the silencer be mounted with at least a 3"

clearance between the ceiling and walls.

Excessive and/or standard temperatures, which emanate from the

exhaust system components may damage or destroy nearby flammable

materials, which may warrant additional clearance or protection.

Caution should also be taken around

wiring & sprinkler systems.

Silencers are heavy and

typically should not be connect directly to the engine exhaust outlet

or turbo. Flex, Wye, or Bellows Connectors allow for thermal expansion

and isolates vibration between the engine and exhaust system. Silencers should be securely mount using brackets or hangers designed to safely support their

weight. All exhaust piping into and out of the silencer must be allowed

to freely expand and not be allowed to put stress on the Silencer or

it’s flanges.

Wall or

roof thimbles conforming to NFPA must be used for any exhaust piping

that passes through any combustible wall or roof.

Most silencers are supplied with a drain

port, and the customer is encouraged to use a rain cap or rain bonnet

on the outlet to prevent rain from entering the silencer.

Exhaust piping should

project upwards for best sound reduction and the use of a rain cap or

rain bonnet is recommended to keep moisture out of the silencer and

engine.

The standard Painted finish is high

heat black paint.

Powder coating and a variety of

corrosion resistant finishes are available and quoted upon request.

All dimensions are inches.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2021

Amstech Power Products, L.L.C.

All rights reserved |

|